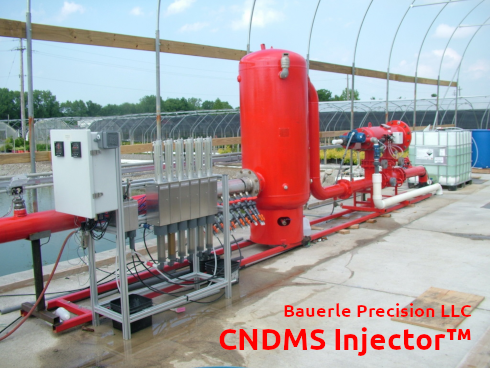

Introducing the Controlled Nutrient Delivery MicroFeed System (CNDMS) Injector™!

Step into the future of greenhouse farming with our revolutionary CNDMS Injector™, designed to optimize plant nutrition like never before. Embrace a new paradigm in plant nutrient delivery based on Ion Composition (IC) Technology™ for unparalleled precision and performance.

Why Choose the CNDMS Injector™?

- Based on Science Unlike traditional EC-based systems, our CNDMS Injector™ utilizes advanced Ion Composition (IC) Technology™ to precisely tailor nutrient solutions based on plant-specific requirements.

- Proven in Business The CNDMS Injector™ has been successfully adopted by businesses, leading to increased profitability through improved crop quality and yield.

- Enhanced Accuracy Experience precise control over plant nutrient delivery with IC Technology™, ensuring optimal nutrient uptake and utilization for maximum crop health and yield.

- Streamlined Automation Save time and effort with automated plant nutrient delivery and monitoring, allowing you to focus on overall greenhouse management.

- Customizable Solutions Tailor nutrient formulations based on ion composition data for superior crop performance and resource efficiency.

- Data-Driven Insights Gain valuable insights through IC analytics to optimize nutrient formulas and make informed decisions for improved plant health.

Features & Benefits:

- IC-Based Precision Our CNDMS Injector™ delivers nutrients based on ion composition, offering unmatched accuracy and efficiency.

- Real-time Monitoring Stay informed with real-time data on ion composition levels and plant response via a user-friendly interface.

- User-Friendly Software Utilize our Windows-compatible client software installed on a laptop for easy control and management of the CNDMS Injector™ directly from your office.

- Expert Guidance Access our team of agricultural experts dedicated to supporting your success with personalized advice and assistance.

Nutrient and Water Management in the 21st Century

Water is a finite source and agriculture uses 70% of fresh water; therefore, the ability to monitor and control the balanced supply of each essential nutrient for healthy plant growth and the reuse of the leached nutrients into the on-site reservoir or containment pond is very important.

The fact is that the impact of nutrient run-off from farms and CONTROLLED ENVIRONMENT AGRICULTURE on water quality has led to regulations that require the whole agriculture industry to retain all polluted nutrient water on site. Most fertilizer systems that are available in the market today rely solely on the measurement of Electrical Conductivity (EC). Nutrient and Water Management in the future with a sustainable irrigation system must take into account the delivery of single nutrient elements. This can be achieved with a new “tool” we call the CNDMS™ (Controlled Nutrient Delivery MicroFeed System).

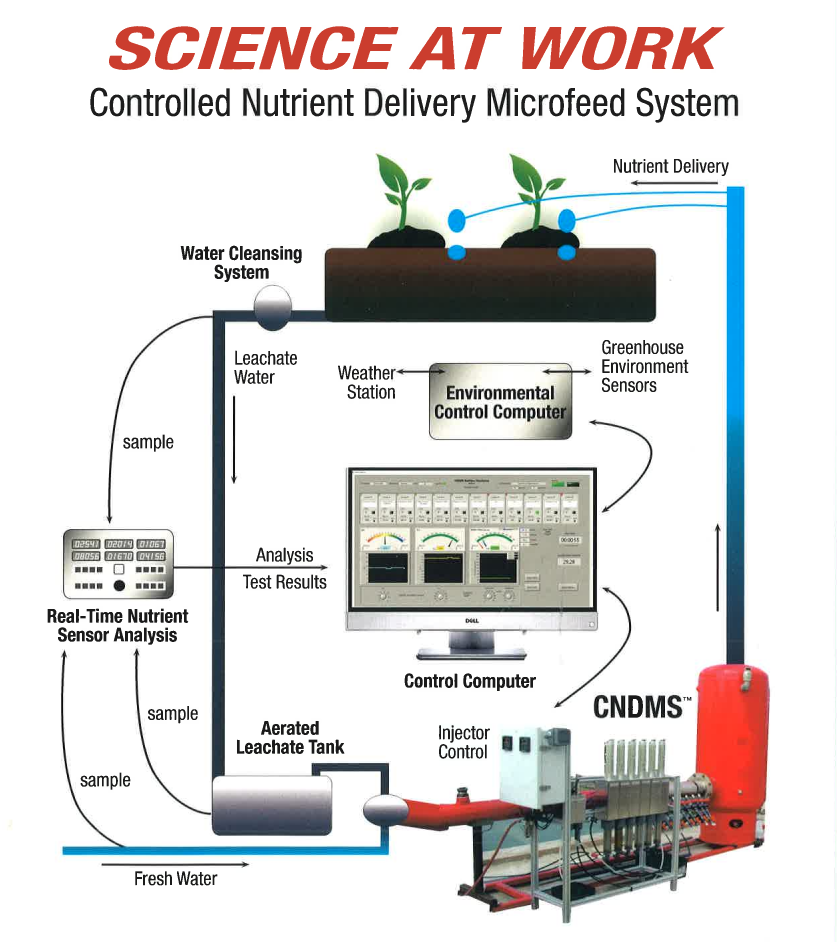

With science-based principles, the CNDMS™ irrigation system is based on the Ion Composition and helps water management professionals and growers reduce their inputs and fixed costs. The ability to implement such a sustainable system can be accomplished by placing various soluble fertilizers into separate stock tanks and being able to precisely inject tailored recipes into the irrigation water “on demand”.

Science at Work: By placing the various plant nutrient salts into individual stock tanks at known dilution rates, it is possible for each single element to be batched at a precise concentration (ppm or mg/l), thus producing a recipe tailored to the crop’s physiological stage or environmental conditions.

The above-mentioned Controlled Nutrient Delivery MicroFeed System (CNDMS™) has the ability to do precisely that and is a safe commercially proven redundant system. It operates independently either with an automatic function or a computerized function as follows:

- The PLC-controlled Automatic CNDMS™ Function will produce a single precise recipe or recipes at the set points of the injectors. To change recipes, a manual adjustment must be performed.

- The algorithm Computer Controlled Function uses the algorithm built into the computer hardware and incorporated into the software and allows for multiple batching of precise recipes. If desired, a simple switch placed in the enclosure allows the operator to switch back and forth between the Automatic (1) and the Computer Controlled (2) Functions.

With the operator’s complete control, the computer algorithm has the ability to apply tailored and an infinite number of precision single element recipes in Real Time. The CNDMS™ injection system can produce any desired recipe concentration without changing the stock tank concentration in Real Time. The commonly used Electrical Conductivity (EC) based 110 volts Pump Control Systems do not have the ability to supply exact ppm or mg/l of separate essential nutrient elements.

Additional Feature of the Single Element (CNDMS™) Batching System

The CNDMS™ “Bolt On” Injection System is a stand-alone system with the ability to independently operate with most off-the-shelf irrigation controllers or can be connected to any Environmental Computer System. It provides a precision recipe of plant essential nutrients, biostimulants, etc. to various individual or multiple irrigation solenoid valves.

Revolutionizing Greenhouse Operations with the Controlled Nutrient Delivery MicroFeed System™ (CNDMS™)

The Controlled Nutrient Delivery MicroFeed System™ (CNDMS™) is an advanced, holistic solution that revolutionizes these aspects, driving cost savings and boosting profitability. With its cutting-edge Ion Composition (IC) Technology™, CNDMS™ ensures precise delivery of nutrients tailored to your crops' specific needs, reducing waste and optimizing growth. This system not only enhances plant health but also significantly cuts down on operational expenses, positioning your greenhouse operation at the forefront of sustainable horticulture.

A standout feature of the CNDMS™ is its ability to recycle irrigation effluent and runoff water, virtually eliminating waste. This is particularly crucial in Canada, where stringent regulations prohibit draining wastewater into the municipal supply. By utilizing every drop of water and every gram of nutrient efficiently, CNDMS™ not only complies with environmental regulations but also dramatically reduces water and fertilizer costs. This sustainable approach translates into substantial savings, allowing you to invest more in other areas of your business.

The CNDMS Injector™ is a vital component of this multifaceted system. Unlike traditional EC-based systems used by competing nutrient delivery or "fertigation" instruments, the CNDMS Injector™ operates without pumping, leading to noticeable savings on your energy bills. Additionally, the system eliminates the need for lengthy preparation times to fill stock tanks, streamlining your operations and increasing productivity. By purchasing the CNDMS Injector™, you enable the adoption of the entire CNDMS™ into your business operations, ensuring your resources are used where they matter most—on the growth and quality of your crops.

At the heart of the CNDMS™ is its IC Technology™, which brings unparalleled precision to nutrient delivery. This technology integrates real-time monitoring and automation, allowing you to maintain optimal nutrient levels at all times. The system's advanced CNDMS Recipe Creator™ software enables you to create custom nutrient recipes tailored to different plants and specific growth phases within a single crop cycle. This level of customization ensures that each plant receives optimal nutrition at every stage of its development, enhancing growth rates and improving overall crop quality. Furthermore, the software allows you to assign different recipes to each solenoid valve in your greenhouse irrigation system, providing precise control over nutrient delivery throughout your operation.

Drawing insights from the Ohio State University Extension Bulletin 956, it’s clear that the principles and advantages of the CNDMS™ are highly relevant to greenhouse operations. The system supports soilless substrates, making it ideal for hydroponic setups where precise nutrient management is crucial. It also offers advanced solutions for stormwater recovery and recycling, reducing dependency on external water sources and ensuring sustainable water management practices. The impact of pH on nutrient uptake is another critical area where CNDMS™ excels, with its acid injection capabilities ensuring that nutrient solutions remain within optimal pH ranges, enhancing nutrient availability and uptake efficiency.

With over 20 years of proven success in the commercial horticulture industry, the CNDMS™ stands out as a trusted and reliable system. By integrating the CNDMS™ into your greenhouse, you embrace a future where precision, sustainability, and profitability converge. This advanced technology empowers you to meet the increasing demands for high-quality, sustainably grown produce while maintaining strict adherence to environmental regulations. Experience the transformative impact of the CNDMS™ on your bottom line and join the ranks of successful growers who have already reaped the benefits of this innovative system.

Experience the Future of Nutrient Delivery!

Make the switch to the CNDMS Injector™ and discover a new era of greenhouse agriculture. Embrace innovation and elevate your crops to new heights with our science-based plant nutrient delivery system.

Contact Us Today for a Consultation!

Explore the transformative potential of the CNDMS Injector™ for your greenhouse operation. Revolutionize your approach to nutrient management and unlock unprecedented growth and efficiency.

|

Bauerle Precision LLC

Central Office: 5674 Dover Road. Apple Creek, Ohio 44606 330-317-0745 |

|